The recycling of contaminated plastic waste, such as post-consumer waste, requires washing and drying after the waste is ground. It is impossible to transform uncleaned waste into granules with Extruders.

Machines used for cleaning and drying dirty waste should be selected based on the form, type, contaminant type, and contamination level of the input plastic.

Sink - Float Tanks are used for the separation of plastics with different densities by taking advantage of the density difference in plastic waste. The model suitable for the processed plastic and processing capacity is recommended by our experts.

Friction Washers play a role in cleaning plastic waste and transporting plastics to the next stage. They are effective in removing contaminants such as sand and mud from the waste.

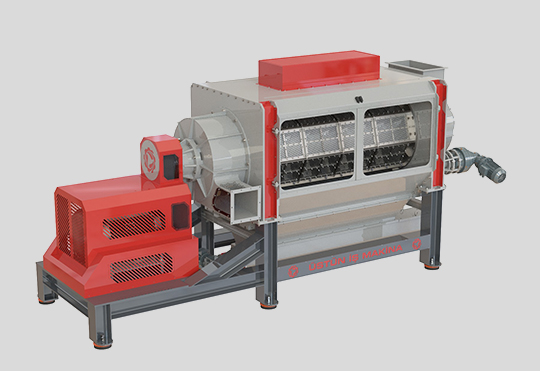

Turbo Washers facilitate the removal of stubborn contaminants through the friction they create. The high-speed friction is particularly effective in cleaning paper residues and organic waste. The continuous rotation of the screen around the rotor, driven by the motor, ensures the constant cleaning of the screen holes, maximizing the washing effect.

Turbo Washers also serve as drying machines for rigid plastics.

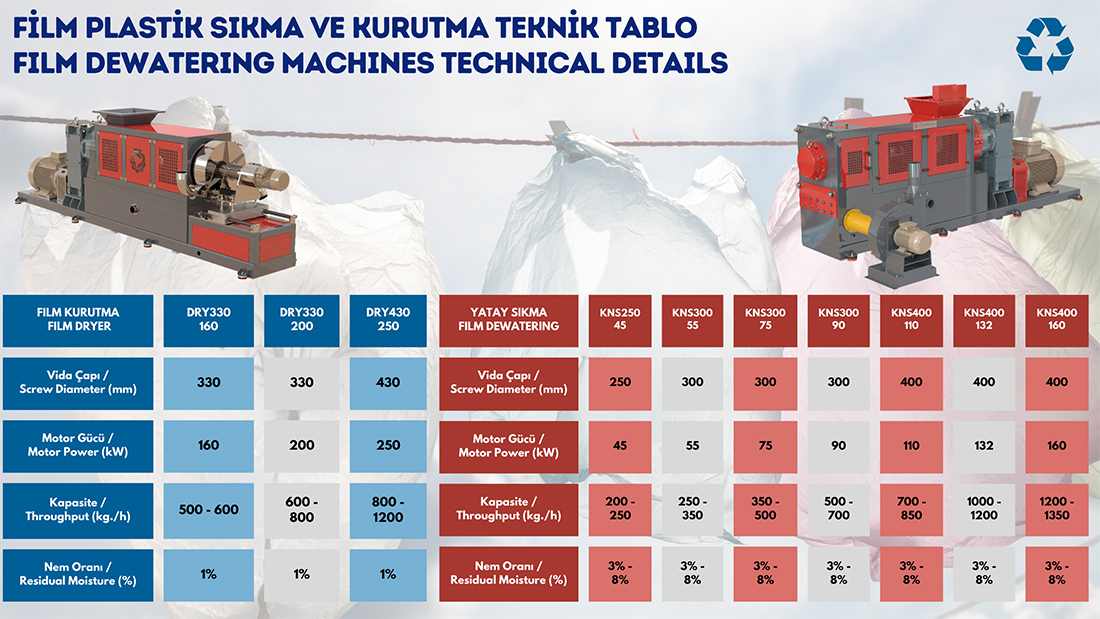

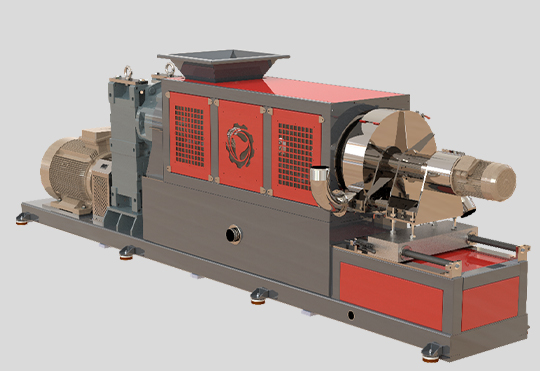

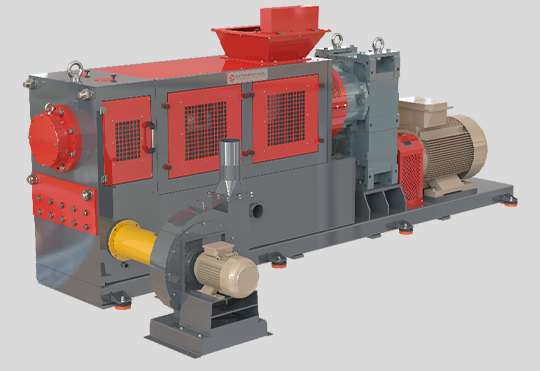

Film dryers are divided into two models. Film Dewatering Machines, without changing the bulk density of the film material, mechanically squeeze the water out of the plastic through the holes of the barrel. DRY-type Film Dryers, through a special screw design, densify the plastic and minimize the moisture content. DRY also increases the bulk density of plastic films, facilitating storage and transportation.