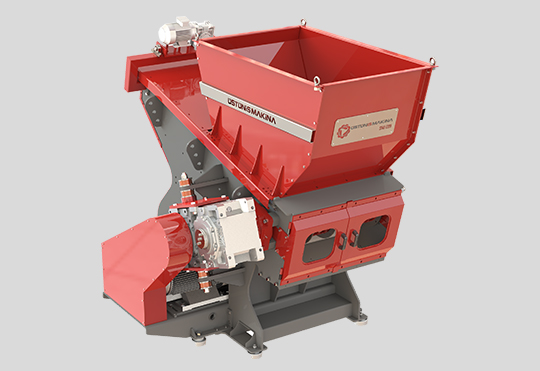

Size reduction is an essential component of Plastic Recycling. For size reduction, we use Shredder (Shredding Machine) or Grinder, depending on the type of plastic waste, its form, contamination level, and processing capacity.

Shredders can smoothly and safely shred all types of plastic waste, unaffected by the waste's type, form, hardness, and thickness. Additionally, they have the capability to shred non-plastic materials such as cardboard, paper, MDF, and textiles.

The hydraulic-powered compression unit presses the waste onto the rotor, where rotating blades on the rotor and fixed blades on the Shredder body reduce the waste until it passes through the screen holes. Shredders operate fully automatically and are PLC-controlled.

Grinders can be used as a second sizing stage after Shredders for further size reduction or directly for the grinding of clean waste.

The rotor type, blade amount, rotor size, and motor power are selected based on the plastic waste to be ground and the processing capacity.

Shredders and Grinding Machines are developed with robust rotor and chamber designs to provide trouble-free service for many years.