PET Recycling Lines are used for the recycling of post-consumer and post-industrial wastes of PET. Recycling lines are designed based on the form of waste PET, processing capacity, the contamination density, and the types of contaminants.

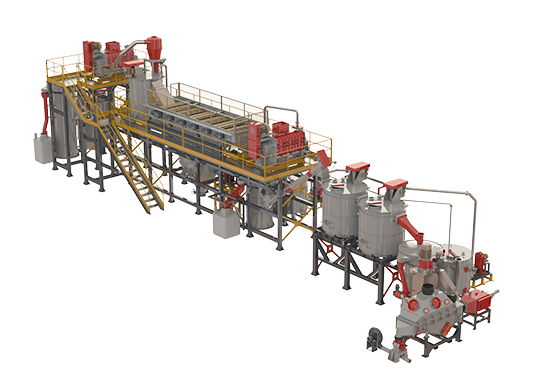

PET bottles are first rid of surface impurities and labels; then unwanted wastes with undesired colors and other plastics are automatically discarded with automatic sorting systems.

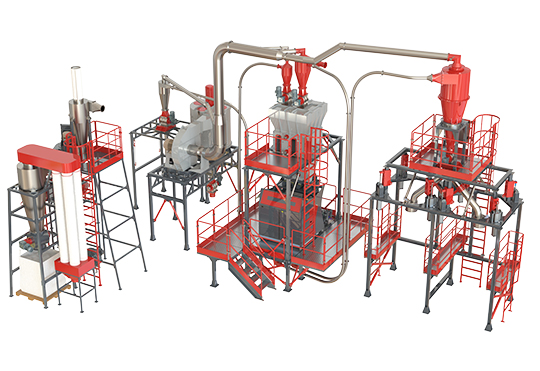

PET bottles, after surface cleaning and automatic sorting, are ground and reduced in size with a Grinder. Subsequently, they undergo thorough cleaning in the hot and cold washing section. After washing, dried PET flakes are directed to an automatic flake sorting machine for final inspection, where different colors and possible other plastics are checked. PET flakes are filled into big bags or sacks in the packaging section.

Wastes separated from post-consumer and post-industrial sources and processed in the PET Recycling Line are turned into flakes. PET bottles, recycled according to customer demand, can be used as flakes, or processed into granule form using granule extruders.

Our company provides turnkey solutions by bringing together Automatic Sorting Machines, Cooling Units, Steam Boilers, and PET Extruders, which are necessary auxiliary equipment for the PET Recycling Line.