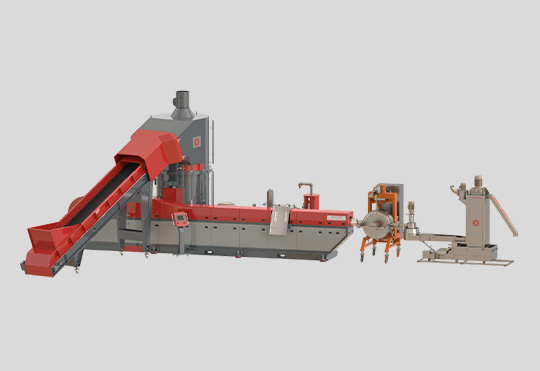

Melt filtration is a crucial aspect in almost every branch of plastic processing. Extruders used in various stages of plastic production, such as recycling, pipe-profile production, film production, cable coating, and sheet production, require filter systems to enhance melt quality.

Polytekprom, aiming to provide turnkey services to the plastic processing industry, has become a solution provider in Automatic Melt Filters, which is a significant need in the Recycling sector.

As of 2019, the BREAK ONE model has been introduced to the market and has quickly become a solution for hundreds of facilities worldwide dealing with the challenge of filtering plastic melt, thanks to its competitive pricing, user-friendly design, and reasonable consumable prices.

BREAK ONE, with its 4 different models having screen diameters of 400 – 500 – 600 – 700 mm, can provide services in the capacity range of 250 kg/hour – 1500 kg/hour. With a minimum filtration fineness of 60 microns, it cleans impurities on the filter surface with 2 scraper blades and drains them using a valve on the filter body.

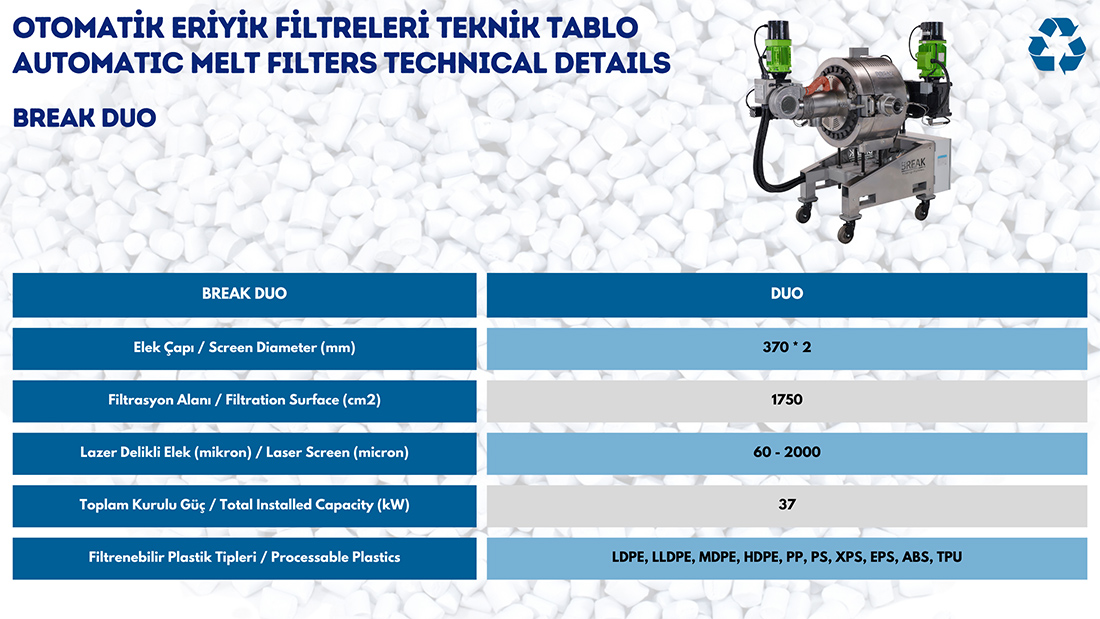

A STEP AHEAD IN AUTOMATIC MELT FILTRATION: BREAK DUO

The success achieved with BREAK ONE has been crowned with the next-generation filtration system, BREAK DUO. The dual-plated and screw-discharge BREAK DUO has been presented to the plastic processing industry after extensive research and development (R&D) and testing.

KEY FEATURES HIGHLIGHTING THE DUO FILTRATION SYSTEM:

High filtration precisionConsistent output pressure

Minimal melt loss

Break DUO offers high-capacity maximum filtration service with its two laser-perforated screens. Thanks to its patented scraper system, it easily and quickly removes contaminants such as paper, wood, copper, aluminum from the screen surface and drains them.

The screw waste discharge maintains a constant output pressure. This ensures no pressure loss after filtration, preventing melt flow fluctuations after the extruder without the need for equipment like gear pumps. By maintaining a steady output pressure, you can preserve your precise flow without using devices such as gear pumps.

BREAK DUO also minimizes maintenance time. With its special design, you can change your filters quickly without having to remove the discharge screw or filter support plates.

These improvements and innovations have minimized melt loss, reduced maintenance time, and lowered the need for personnel.

BREAK DUO serves in the filtration of polymers such as LDPE, LLDPE, MDPE, HDPE, PS, ABS, and similar materials, offering filtration fineness ranging from 60 microns to 2000 microns, depending on the specific requirements.