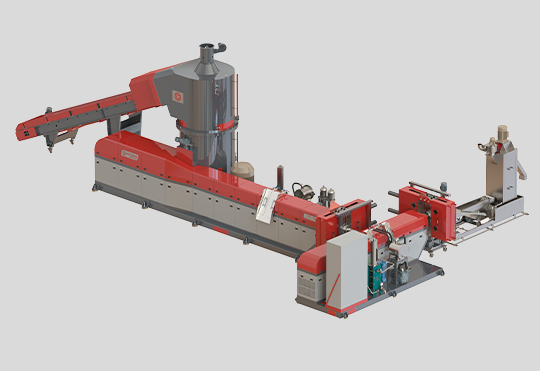

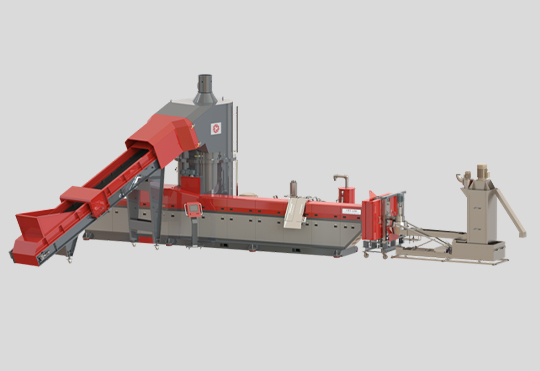

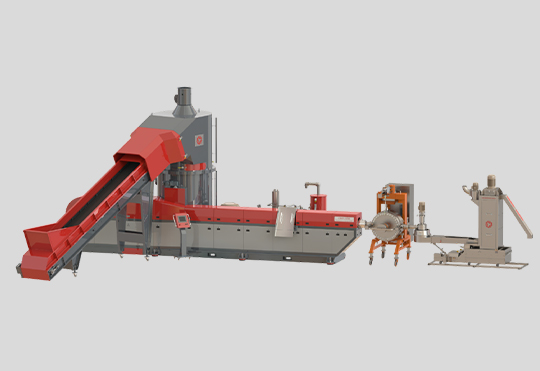

The transformation of plastic waste into reusable raw material in granule form is provided by Recycling Extruders

Shredded, cleaned, and dried plastic waste undergoes final drying in an integrated CRT Extruder. It is subjected to mixing and homogenization in a single machine, melted with a specially designed extruder screw, and unwanted gases emitted during melting are vacuumed. The molten plastic is carefully filtered during the extrusion stage, removing the last impurities remaining in the plastic. The plastics, transformed into granule form with a pelletizer, are cooled and packaged.

The CRT Extruders have the capability to process all forms of LDPE, LLDPE, MDPE, HDPE, PP, PS, ABS plastics (flakes, fluffy, foam). Thanks to the integrated automatic Densifier system, plastics with a moisture content of up to 7% can be smoothly granulated. The CRT series Extruders are designed to provide trouble-free service for many years with a robust chassis, a thick Densifier tank made of AISI304 stainless steel, bimetallic screw and barrel, durable special series gearbox, and FAG brand bearings.

The CRT Granule Extruder requires minimal space with its compact and integrated design. Values suitable for processed plastic can be automatically loaded into the system with the recipe saving feature. Operating without the need for an operator due to the fully automatic PLC control, CRT Extruders are the extruder model with the lowest unit operating cost thanks to their highly efficient operating principle.

Our company offers turnkey solutions by providing users with the necessary auxiliary equipment for CRT Extruders, such as Metal Detectors, Melt Filters, Cooling Units, and Ovens for Filters.